SHIELD TECHNOLOGY

Motorcyclists are exposed to many hazardous elements while traveling at speed, including road debris, insects, rain, and the sun’s damaging UV rays. Eye protection is essential when riding, and is actually required by law in North America. To help improve safety and ensure the most comfortable riding experience possible, SHOEI uses only the highest quality materials and most sophisticated manufacturing techniques to meet and/or exceed DOT and SNELL standards. All SHOEI shields (stock and optional accessory shields) block 99% of the sun’s harmful UV rays, and our 3D injection-molding process ensures a distortion-free view throughout the entire field of vision.

SHIELD STANDARDS BROKEN DOWN

There are many different eye protection standards internationally, and many of our National standards actually vary from state-to-state. DOT uses the currently valid Vehicle Equipment Safety Commission Standard 8 (VESC-8), which designates material, lens size, optical properties, strength, field of vision, flammability, cleansing capabilities, labeling, identification, and testing procedures to which all eye protection devices must meet and be used by motorcycle riders and passengers. SHOEI shields also meet/exceed the American National Standard for Occupational & Educational Personal Eye and Face Protection Devices (ANSI Z87.1), which is a requirement specific only to motorcyclists in the state of New York. Additionally, SHOEI shields must also pass the tough SNELL requirements. In order to meet this standard, a small 1 gram lead pellet is shot into the shield at roughly 310 mph and must not penetrate the inside of the helmet.

PRODUCTION AND R&D

All current model SHOEI shields are made from high-strength polycarbonate using a sophisticated 3D injection molding process. Although this method is more expensive, it is necessary to create a 3-dimensional curved shield that is optically correct to eliminate any distortion. Injection molding also allows SHOEI to form the mounting apparatus that work together with SHOEI’s quick-release base plate systems, allowing for quick and easy tool-less shield changes. In contrast, some manufacturers are forced to use turbulent base-plate covers because they cannot produce 3-dimensional shields using the “stamping” method.

CLARITY IN OPTICS

People often underestimate the value of optics, but not SHOEI. We believe that optimal vision will also enhance rider safety and benefit your overall riding experience. After all, many people ride motorcycles to experience the world, so why take any of that away with inferior optical quality? All current model genuine SHOEI shields (except flattened racing tear-off shields) are 100% optically correct — a feature that requires a sophisticated process to accomplish. In fact, SHOEI’s optics are so good that the Japanese military contracted SHOEI to produce airplane and helicopter pilot helmets, including the face shields. Other manufacturers are unable to meet the Japanese Military optical standards.

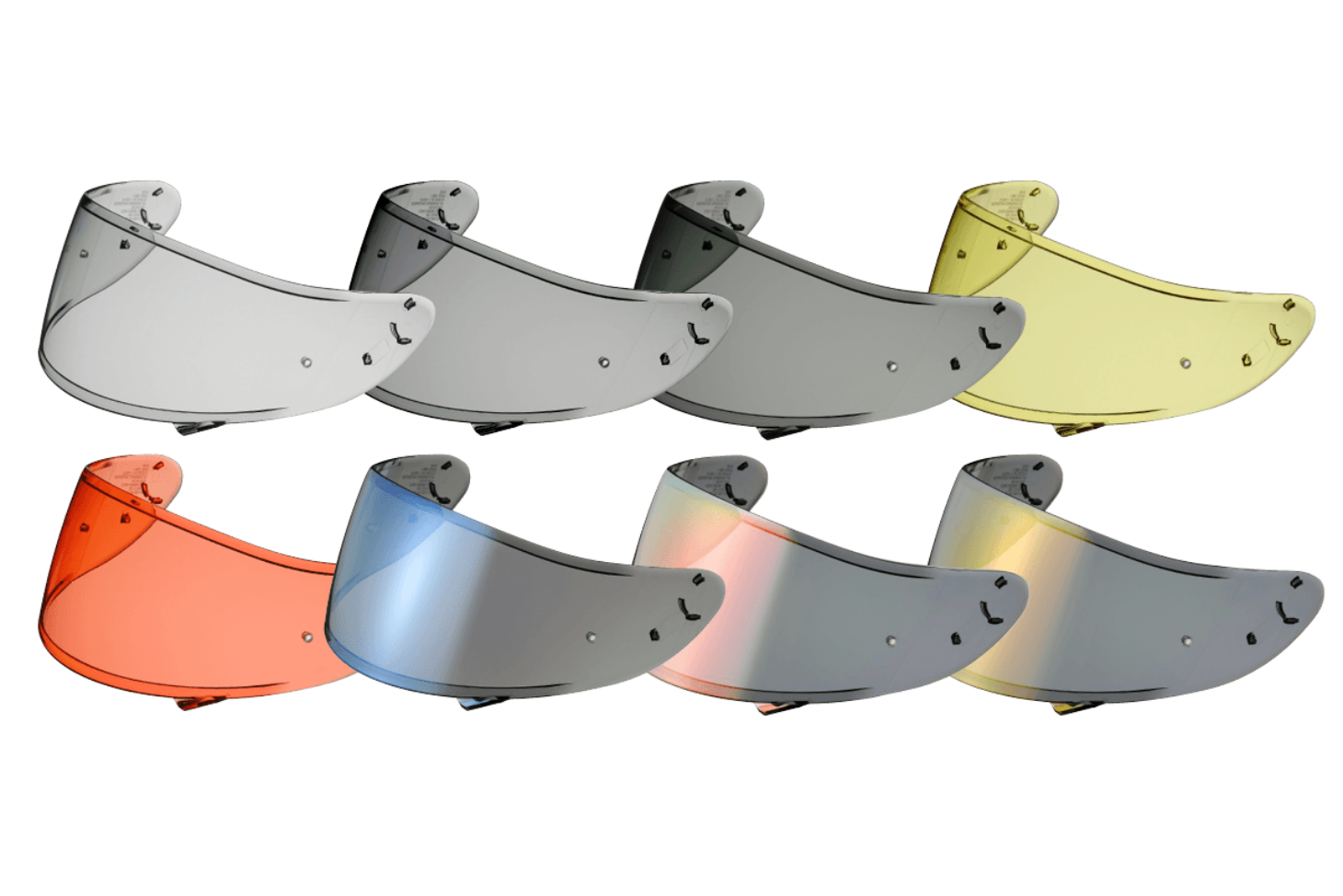

DOT/VESC-8 LIGHT TRANSMITTANCE & OPTIONAL TINTS

The DOT/VESC-8 standard requires a light transmission of at least 80% for shields, so it can be used around the clock without any problems. Tinted shields with a lower light transmission of 50%-80% receive the additional “For Daytime Use Only“ label, and are only suitable for use during the day.